EVA cases have become the first choice for B-end customers due to their excellent protective performance and various design choices. This article will analyze the different materials of EVA cases in detail, from surface material, middle EVA layer to lining material, to help you choose the most suitable EVA case.

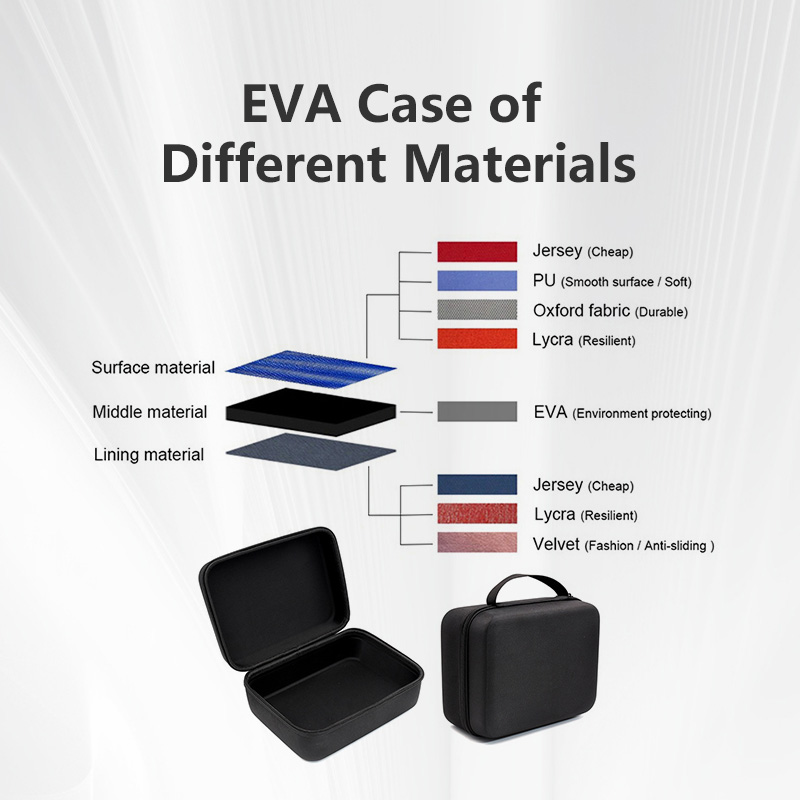

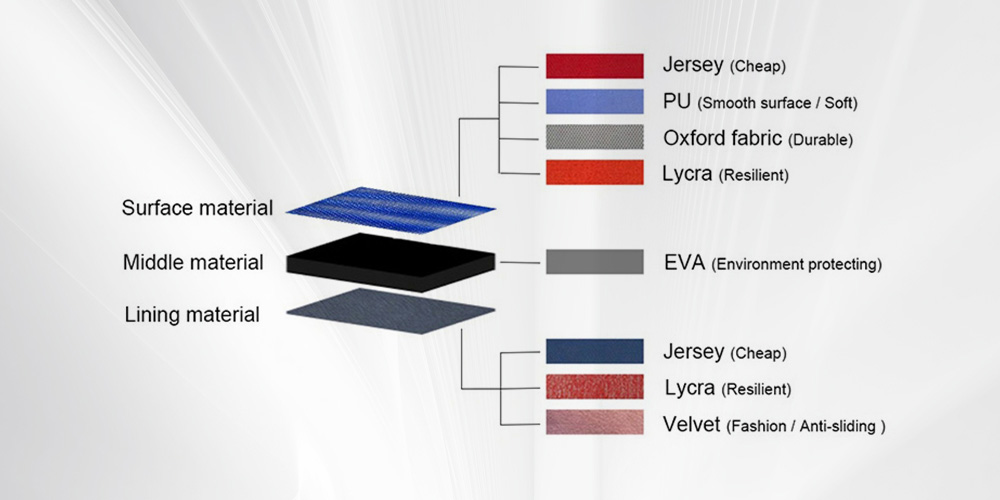

Surface material of EVA case

The surface material is the outer layer of the EVA case, which directly affects the appearance and feel. Common materials include:

- PU leather: high-end texture, wear-resistant and waterproof, suitable for high-end products.

- Nylon cloth: wear-resistant and tear-resistant, suitable for products that are frequently transported.

- Polyester cloth: Waterproof and dustproof, easy to clean, ideal for daily necessities.

Middle EVA layer

The EVA layer is the core of the EVA case and determines the shock-proof protection performance. EVA material is flexible and has significant cushioning effect. According to product requirements, the thickness and density of the EVA layer can be adjusted:

- High-density EVA: suitable for precision instruments and electronic products.

- Medium density EVA: suitable for general protection needs, such as cosmetics.

- Low-density EVA: suitable for lightweight items with lower protection requirements.

Lining material

The lining material directly contacts the item, affecting the use experience and protective effect. Common materials include:

- Flocking cloth: soft to the touch, prevents scratches, suitable for high-end gifts.

- Velvet: Soft texture, non-slip, suitable for electronic products.

- Fleece cloth: durable and wear-resistant, suitable for tool products.

in conclusion

Choosing the appropriate EVA case material can improve the packaging effect and protection performance. By understanding the surface material, middle EVA layer and lining material, you can choose the best combination according to product characteristics and needs to create a high-quality EVA packaging case.